Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🛠️ Lock in strength, unlock flawless craftsmanship!

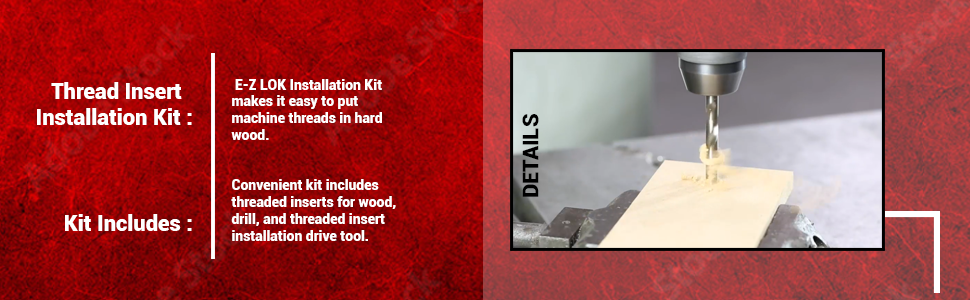

The E-Z LOK 400-4 Thread Installation Kit is a precision-engineered solution for embedding durable machine threads into hardwoods like oak, cherry, and maple. Featuring proprietary knife-edge brass or stainless steel inserts, this kit ensures superior holding power and corrosion resistance. Complete with a drill and installation tool, it’s designed to prevent thread stripping and erosion, making it ideal for professional woodworking, furniture assembly, and high-stress fastening applications.

L**.

FANTASTIC!!!

We bought this because we needed to add bun feet to a new cabinet we built for our dining room. The old way of doing this was a pain in the rear, but with this new threaded insert tool...I'm looking around the house to see what else I can add bun feet too. My husband was so thrilled to use it and to put on the feet. He had that expression of "Where have you been all my life..." on his face. That's a good expression to have. I could not get over how fast the installation went and viola we were standing in our dining room admiring our new cabinet. Game changer plain and simple.

V**T

Easy to use; excellent quality

These brass inserts are the perfect combination of material and manufacturing quality for use in securing stainless steel bolts to hardwood. The brass with knife threads easily cut into hardwood. It’s a much more reliable way to securely hold a bracket or other bolted on item to the wood while also allowing the bolt to be removable and refastened if needed.These e-z lok inserts have much tighter tolerances and finish than the cheaper knockoffs I’ve used before.The installation tool in the tool-and-insert kit makes installation very easy with a cordless driver. (Although a less efficient makeshift installation tool can be made with a matching machine screw or bolt and two hex nuts as shown in my photos. What I do NOT recommend is using a flathead screwdriver to install these inserts into hardwood… very slow and painful by hand or even with cordless driver.)

D**E

Great Inserts, but....

These are great inserts overall. I use them for making custom beer tap handles, but need to be aware of the limitations of the installation tool for certain species of wood.If you are working with Walnut the insertion tool will work fine on a heavy enough drill, but if you are working with Cherry or Maple, forget about it. For the super hard woods I use the insertion tool to get maybe the first 2 threads into the piece as it does help keep the insert straight. After that switch to a hardened 1" bolt and a breaker bar to get them flush.No need to use any glue on the insert, they are never backing out once they are in place.

M**L

Inserts and drill quite nice; insertion tool not useful

The inserts are great. The drill bit in the kit is a nice upgrade from the ordinary drill bit I had been using with these inserts: it has sharp narrow centering point to get nice holes right in position. The insertion tool was useless, though; it chewed up the brass insert (and got chewed up in turn) the first time I used it. Much easier just to use a screw into the internal threads to drive in the insert; you can also just put the screw in the other side if you need to back the insert out, which you cannot do at all with their insertion tool.

R**E

Use as directed or suffer

I see a lot of good reviews and lot of bad reviews. To clarify things a bit: these are a well known and often used inserts for woodworkers of all sorts. Installing these inserts correctly requires that you have either a drill press, tapping arbor or have at least taken steps to ensure that the angle of installation is perfectly and consistently 90 degrees to the entry point. You will need to pre drill a pilot hole for these and the supplied brad point bit is a perfect fit in maple, but nothing in woodwork is a guarantee. Very dense exotics and the like would benefit from (and may require) an additional tapping step before installation. The installation tool is really handy and safer than a homemade lock nut because it's hardened. Thinking of doing this by hand and eye? Just don't - You have a good chance of getting these stuck at a bad angle and wasting your project. I've installed dozens of these with great results, but I struggled before figuring them out - Use as directed or Suffer.

I**.

Broke inserts and drive tool while working with walnut

I'm not usually one to leave reviews, but I have to share how terrible my experience with this product was as a warning to others. I was working with walnut, building an electronics enclosure. I intended to use these inserts as bases for PCB standoffs. I used the provided 17/64" drill bit with a drill press, and the provided drive tool with a hand screwdriver, so I was certain that the holes were straight and the inserts were being driven with an appropriate amount of speed and torque.Well, first, I broke at least three inserts midway through installation. The protrusions on the drive tool crumpled and gouged the brass. (See photo.) I had to remove the insert partway and start over several times.Then, the drive tool itself broke! One of the protrusions that go into the slits on the inserts sheared off. (See photo.) I got a wide flat-blade screwdriver and used it to drive the inserts instead. It honestly worked better, and I managed to finish the job without damaging any more inserts.In the end, the inserts functioned fine, but not without some cosmetic issues. The inner M3 thread is good, and I had no trouble screwing nylon standoffs in and out without damaging them. However, the inserts caused minor cosmetic damage to my enclosure. They split the grain, causing it lift away from the face of the workpiece. (See photo.) I mitigated the damage with some superglue and sanding, and it didn't matter much in my case, but I'd caution against using these inserts in places where they might be visible.On reflection, I suspect that these inserts were not tested sufficiently on hardwoods. I'm guessing that many of the issues I encountered wouldn't have happened if I was using pine or another wood softer than walnut. If you must use these inserts on hardwoods, try using a drill bit that's larger than 17/64". Maybe 19/64″ or even 5/16″. The outer threads are about 21/64" in diameter, so assuming that you don't need it to bear any notable load (it's an M3), 19/64" should work just fine. Just take care to keep the insert aligned.tl;dr I broke several inserts and the drive tool during installation into walnut. Consider alternatives.

Trustpilot

1 month ago

2 months ago