![Plasma Cutter, [Pilot Arc][Large LED Display][Air Sensor] 50A bestarc Plasma Cutter Machine 110/220V Dual Voltage, 1/2'' Clean Cut 3/4 Inch Max Cut, Post Flow Mesh, 2T/4T for Beginners DIY](https://m.media-amazon.com/images/I/71GqrsJM6FL.jpg)

⚡ Cut Clean, Cut Smart — Own the Metal Game!

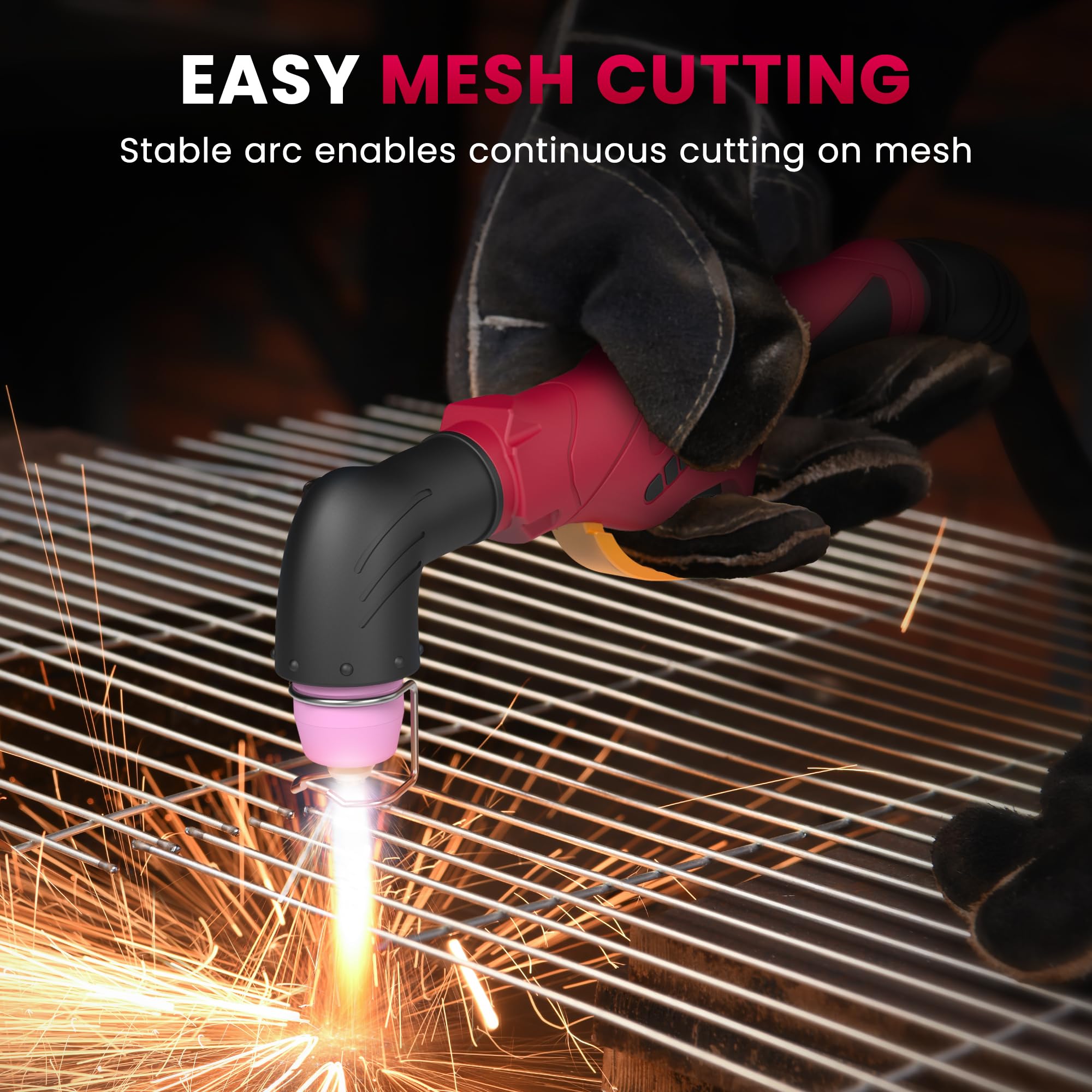

The bestarc BTC500DP 8GEN Plasma Cutter delivers professional-grade 50A cutting power with dual voltage (110/220V) flexibility. Featuring advanced Pilot Arc technology, it effortlessly cuts through rusted or painted metals without surface prep. Its large LED display and built-in air sensor provide real-time operational insights, while ergonomic 2T/4T controls enhance user comfort and consumable longevity. Perfect for DIY enthusiasts and pros aiming for precision and efficiency in metal cutting.

| Manufacturer | bestarc |

| Part Number | BTC500DP 8GEN |

| Item Weight | 16.07 pounds |

| Product Dimensions | 13.98 x 5.12 x 8.46 inches |

| Item model number | BTC500DP 8GEN |

| Color | Cyan |

| Style | BTC500DP 8GEN 110/220 |

| Material | iron |

| Power Source | ac |

| Voltage | 110220 Volts (AC) |

| Wattage | 12000 watts |

| Item Package Quantity | 1 |

| Included Components | Built-in Regulator, Air sensor, Plasma cutting torch, Portable, 18mm Max cutting thickness @220V 65PSI, Set up within 1 min, Easy to use, Powerful performance, bestarc plasma cutter, cortadora de plasma para metal |

| Batteries Included? | No |

| Batteries Required? | No |

C**N

This little box is stout. I knew only what was reviewed when I ordered and I wasn't disappointed.

I ordered this brand on a discount during a sale. I needed a plasma cutter for multiple projects around the shop. Not knowing the build quality or the brand I took the modest claims of material thickness, cut them in half and and figured if it could at least get through 1/4" I wouldn't consider it money wasted. After clean cutting stacked 3/16 plate, I was impressed.Having a plasma saves so much time compared to cutting with a death wheel, and if you've ever lodged part of a fiber disc in a wall when one comes apart you know know that it is an appropriate name. The instructions are decent and give you a decent baseline to experiment in getting quality results. I found all the setting close to accurate except for the air. I found that I needed to run more than the recommended setting in order to clear the slag. This however is subjective, all of us will have different compressors, regulators, and atmospheric conditions that will play a factor.I have not needed to touch the box aside to adjust the settings since I set it up.The process of value engineering also has its drawbacks. In this product it is minimal but present in the air line and supplied fittings in the kit. They give you a modest piece of the poly air line material that swells like a birthday balloon when you use is. The fittings are fictional but you will likely want to upgrade. I opted to get one of those 8" premade hoses remnants from HF, and attached some quality fittings to make a decent whip for my cart. Since that initial setup, I have run this little machine like a rented mule and it has not given me a problem.

D**N

Superb Quality

This is a fantastic unit. I bought it because my guru "Tim Welds" on Youtube recommended it. Well, of course it went on sale for a little off and I bit.I've been using it for a couple of weeks now and it's proven it's worth with my side hustle.No, it's not as robust as the HTP at work but if you pay attention to what you're doing, adjust the settings properly, this little rascal cooks!You won't be disappointed. I bought what I consider a lifetime supply of consumables for around 25.00. I think I'll check to see if I can get a spare gun just in case I do something stupid.Buy it.

J**E

Awesome plasma cutter

This thing is awesome, I wasn't expecting so much for so little $$$I work at my job with a Hobart that is over $1500 and double the size, the only thing better of the Hobart is the torch length which is around 20ft, this one is 10ft, that's the only drawback.Stop looking around and buy it before prices skyrocket. Hope you find this review helpful.

B**B

Quality issues. Be aware if you only have 110 V available.

Update:New item: If you have dreams of using this unit in some sort of CNC plasma cutter, from what I can tell, it is Not compatible with the most popular and low cost plasma cutters like the Arcdroid and Langmuir. Not an issue for me, but it's worth noting.I've updated the review to 4 stars. Bestarc Customer Service does respond by email and I'm working with them to resolve my questions. According to them, in order to operate at full 110V rated amperage at 35 Amps, you need a 40 Amp breaker. I'm no electrician, but I don't know anyone with a 40 Amp 110 V circuit. I happen to have a 20 Amp circuit in my garage, so I can do 20, or maybe 25 for a very short period of time. I was going to get an extension cord from my dryer to run the unit at 220 V (max 30 Amps I guess?), but I do have a 4000 W generator with 220 output and will try that first. I don't see cutting max thickness metal very often, but the machine gives you the impression you can run 35 Amps at 110 V without being very clear what the machines house breaker requirements are.It appears the arc extinguishing problem has to do with the air pressure supply. I've got a compressor with a 30 gallon tank, so I have plenty of air, but like any air pressure regulator, you need to make sure what the pressure is when air is flowing. I think the problem with arc extinguishing is that the air pressure drops below the minimum required once it starts flowing. I've set it higher and make sure the display stays in the green when cutting, and the extinguishing has practically gone away.I think this is a great unit for the price. But if you expect to cut the maximum metal thickness advertised, you may be disappointed.Original:I was very excited when I saw several YouTube videos about this low cost plasma cutter. It seemed ideal for the home metal working tinkerer like myself. I ordered one and was immediately disappointed when it arrived. I opened the box, and the knob for the air pressure regulator was damaged. I don't think it was a shipping issue as the box was in perfect shape. It looks like it was just slapped I the box with the obviously broken knob. So I returned it and ordered another. This one seemed fine out of the box and I set it up to try cutting some scrap steel I had.First problem I had was the circuit breaker for my 20 amp 110 V line keep popping at the maximum current of 35 Amps. I may not understand how the system works, but I'd think that even if the system is set for 35 Amps, the input from the line would be less than that. In any event, I cut the current to 20 amps and mad my first cut thru some scrap 3/8 steel I have. The first cut went fine, but when I went to cut it again, the arc kept extinguishing after about 5-10 seconds of cutting. The breaker did not pop, the arc just went out. Even when the torch is off the workpiece, the arc keeps popping out.I've sent BestArc support an email since their phone number does not seem to work. There is a very good welding channel on YouTube that just reviewed this welder. I won't post the link because I think Amazon rejects those. But think on fire welding and you should be able to find the review. He liked the Bestarc, but had the same problem I am having at 110 V. It worked fine for him at 220V. I don't have 220 readily available, so I can't try that. I've noticed other amazon reviews of this plasma cutter are having the same issue. If and when I hear from Bestarc product support and get this resolved, I'll revise this review. It would really speak badly of this company if you need to get 2 replacements in order to get one that works.

J**M

Very nice machine

Works very good light weight and compact. I ran it on 220v at 50amp and was able to cut through some thick steel with ease. Make sure you have a good clean ground for best results.

R**N

Great little unit well worth the money.

You are not going to find a better plasma cutter for this kind of money. This thing works really well. Some people had mentioned that their circuit boards had gone bad. One thing that may be happening is when you're done cutting the cooling fan is going to continue spinning until it cools down. You have to let it cool all the way down and it will shut the fan off automatically, then you can turn the unit off. If you turn off the plasma cutter before it is able to completely cool off and let the fan go off automatically, that built up heat may be what's causing the boards to fail.

P**S

Bestarc plasma cutter

Seem to be well made. Light weight and portable. Easy to use. I use it to cut rusted sheet metal out of cars and it does the job.

Trustpilot

1 day ago

2 months ago